In the world of food, packaging is one of the most delicate and essential steps in the production process for a number of reasons (food preservation and shelf life, visual appearance of the finished product, etc.).

A food company – whatever its sector: bakery, fruit and vegetables, pasta, meat or anything else needs to rely on a packaging system able to ensure safety, continuity of preservation, quality and flexibility.

Therefore, it is very important to choose the right partner. Relying on a trusted, serious and experienced partner guarantees a fruitful relationship, without nasty surprises, just like in life…

Thanks to a great team of reliable and experienced professionals, who closely follow each client all the way through, TECNO PACK can boast of long-standing relationships with clients all around the globe.

For all these reasons, small, medium and big food companies, such as Barilla, Granarolo, Kraft and Nestlé, have entrusted TECNO PACK with the packaging of their production.

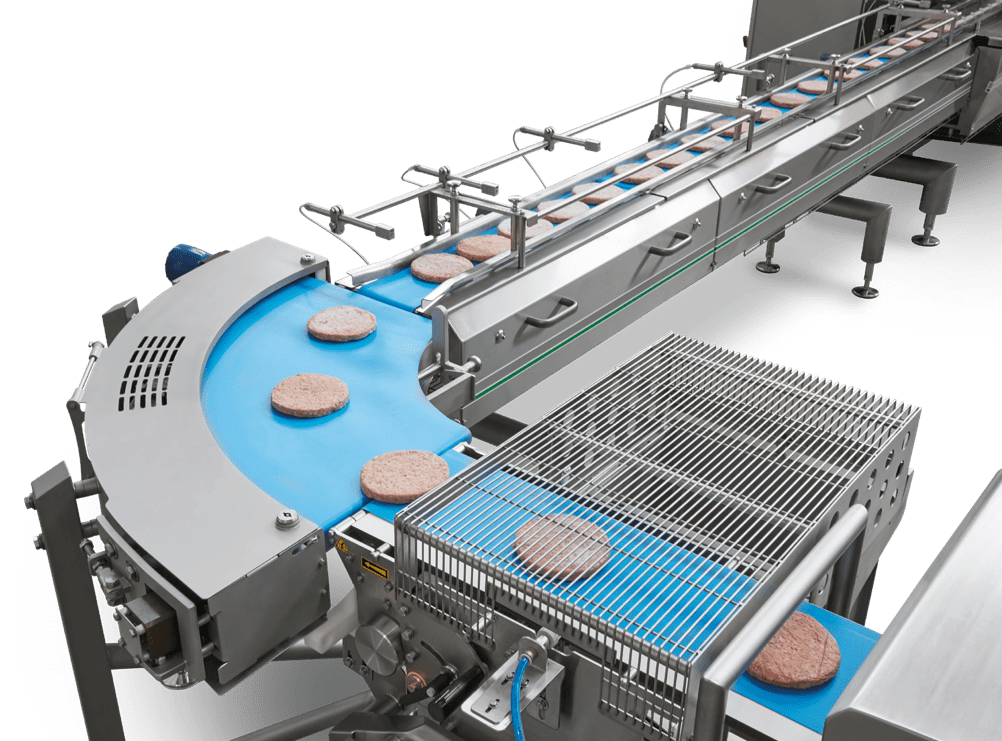

The Group provides a complete service dealing with the product from the process line to the pallet, ensuring a complete and constant assistance, also during the start-up of a plant. Its extensive experience allows TECNO PACK to operate in any type of food sector as well as to satisfy even the most demanding requests coming from companies in need of complex solutions or tailor-made designs.

Being able to solve complicated technical issues and to handle difficult situations with attention and determination, TECNO PACK is the ideal partner.

The price-quality ratio, the after-sales service and the spare parts service are just some of the strengths of the Group, which boasts highly qualified and committed staff in every department, beginning with the management.

The constant research and the technological evolution have helped creating highly flexible and long-lasting packaging lines.

TECNO PACK offers extremely high-quality packaging lines, modified atmosphere packaging solutions – suitable for the food industry as well as for other sectors such as the biomedical and pharmaceutical industries -, vertical and horizontal packaging lines, vacuum packing, plastic or cardboard trays filling, end of line systems, case packing, pick-and-place lines and palletizing systems.

One of the latest line is FP100E, a high-speed horizontal wrapping machine.

Whenever there is a need for packaging, there is TECNO PACK.

www.tecnopackspa.it

www.ifppackaging.it

www.gsp.it