PMR System Group s.r.l.s.u.

Our packaging solutions to expand your business

We only use high quality raw materials

High reliability and ease to use

- Description

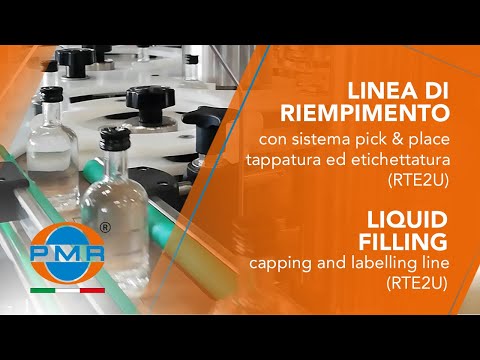

PMR System Group is a leading manufacturer of filling capping and labelling machines; all solutions that provide an extremely positive contribution to companies that exploit it.

The wide range of PMR proposals is addressed to the whole productive sectors and meets the most varied technical requirements. All components of our machines are completely “Made in Italy”.

No business district is precluded: from the industrial to the artisan one, from the serial to the prototype, all for a valid solution, standard or customized.

We cover all sectors: from food to chemical, from cosmetics to construction industry, from pharmaceuticals to technology.

Be it small, medium or big industry, for our Group the importance and value of a project are exactly the same, without any kind of distinction.

In 1971, with a brilliant intuition, Cosimo Rubino draws the firm conviction and essential strength to inaugurate, among the very first pioneers, a new era for the packaging industry in Italy. In 2005, his son, Omar Flavio Rubino, took over the management reinforcing his father’s experience and introducing a creative and innovative approach to PMR, daily bringing a winning energy for the company and its customers.

Many steps marked the company’s growth in the name of research and technical innovation.

From LABELLING SYSTEM division, which includes all the proposals relating to labelling systems, marking and coding products, bench and industrial applicators, to EXPERIENCE department, which includes all solutions regarding dosing, filling, linear and rotary capping machines, with many customized solutions.

To date, the constant technical sales development allows us to combine in a single solution design, production, sales and technical assistance with new protection formulas to Italy and abroad.

Precise and accurate answers, this is the first of our objectives which is called the whole company staff; harmony, full cooperation, skills, enthusiasm and passion are the key factors for the success of our Group.

The commercial organization, with direct contact or through the presence of agents and authorized distributors, covers the entire Italian territory and allows us to reach all continents.

The experience, knowledge and abilities of our designers and engineers enable the constant monitoring of production processes, accordingly with the established delivery terms. Through national and international exhibitions PMR always offers novelties, accepting tougher challenges aimed at a constant and continuous improvement.

- Gallery

- Videos

- Articles

Packaging and Branding: More Than Just a Box

Packaging is often perceived as merely a functional container, a protective layer for products during transport and distribution. However, in today’s world, packaging is much more than that. It has evolved to become a key element in a company’s marketing and communication strategy. In an increasingly competitive market, packaging plays a crucial role in differentiating

Revolutionizing packaging: the trends shaping a sustainable future

In recent years, the packaging industry has undergone a radical transformation, driven by efforts in sustainability and regulatory changes. These factors are pushing the adoption of new technologies ranging from mechanical engineering to recycling, redefining the very concept of packaging and the materials used. The focus on sustainability has highlighted the urgency to reduce the

- Informations

- Related Advertisers

- Categories

- Tags

- Contact the editorial staff of PACKAGING INTERNATIONAL for more info